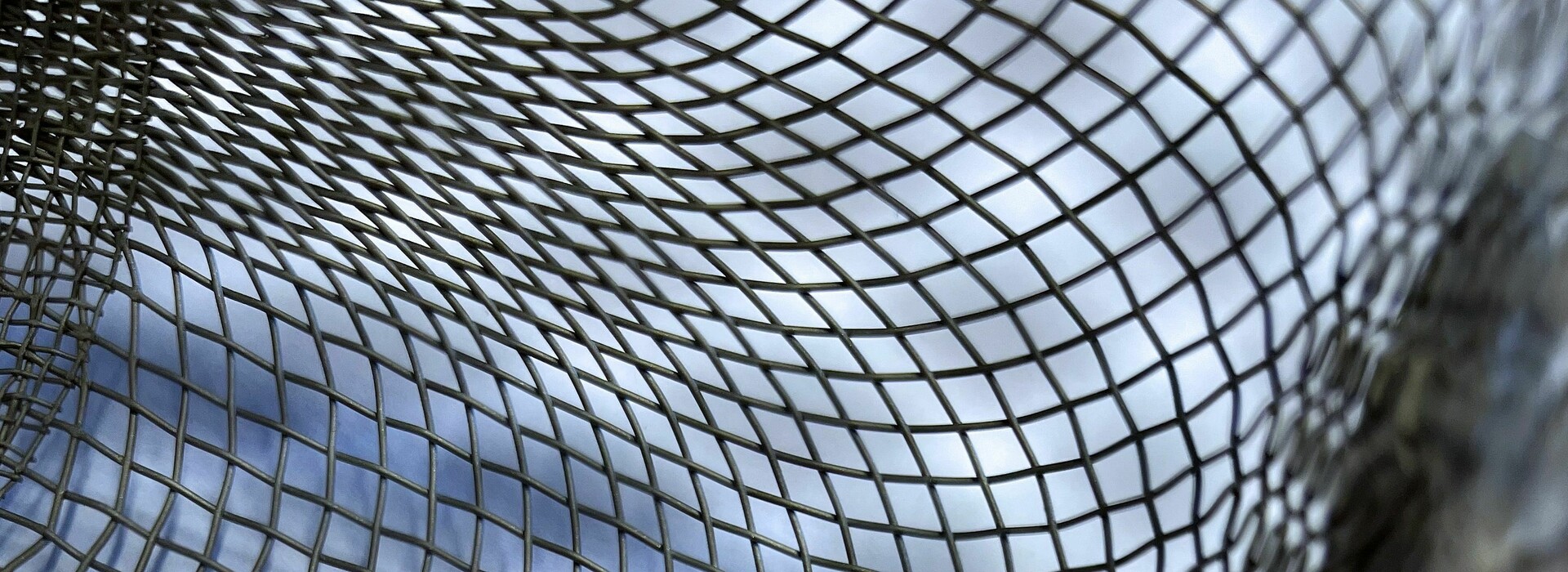

Wire mesh

Holmik manufactures EMI shielding, filters, protection, and other applications requiring precise mesh openings from woven wire mesh, also known as sieve cloth.

Some of the most important properties of wire mesh are its stability, resistance to high pressure and high temperatures, and long-term durability. We guarantee that the wire mesh we use is manufactured with the highest quality and precision.

◊ Filters made of wire mesh (sieve cloth)

◊ EMI/EMC shielding with wire mesh

Areas of use

What can wire mesh be used for? There are many applications, and new ones are constantly emerging. Below are some examples of industries in which wire mesh is used:

· Process industry (e.g. chemical and oil industry)

· Electrical and electronics industry

· Energy

· Automotive industry

· Home, household, and garden

· Design and architecture

· Pharmaceutical industry

· Food industry

· Solar cells

There are, of course, many more applications. If you believe that you might have a use for our wire mesh, do not hesitate to contact us for advice. We have extensive experience with the material and if, by any chance, we cannot answer your questions, our skilled collaborative partners can usually help you.

Materials

Examples of materials in which wire mesh is woven include:

· Stainless AISI 304 and AISI 316

· Brass

· Copper

· Iron

· Galvanized materials

· Phosphor bronze

· Titanium

· and more

How is woven wire mesh manufactured?

The metal wires used in woven wire mesh are produced by drawing a metal rod through a series of dies until the desired wire diameter is achieved.

Weaving metal wire into a mesh is similar in many ways to the process of weaving fabric. First, a weaving machine is set up with long lengths of wires threaded parallel through the machine. When the machine is in operation, it alternately lifts the wires, allowing a shuttle to pass through. The machine then presses the fill wire against the mesh and lifts the opposite wires so that the shuttle can pass in the opposite direction, resulting in an over-and-under weave.

This is a simplified description of the weaving process. Other weaving patterns can also be created.

L = Mesh opening

D = Wire diameter